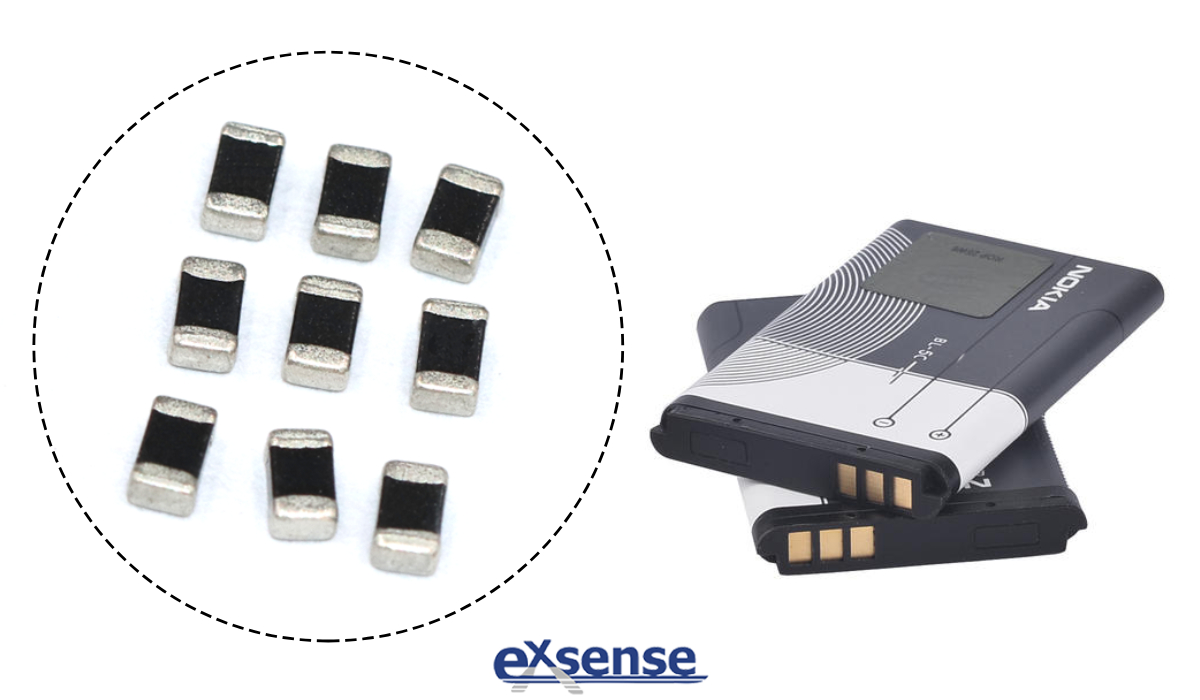

Reliable SMD Type NTC Thermistor and Lithium Battery

Lithium battery has a long cycle life, small size, light weight and no pollution, so it’s widely used in mobile phones, laptops, electric vehicles, reserve power supply of street lamps, small home appliances and so on. The resistance of NTC thermistor decreases as the temperature increases, so it plays an important role in the temperature measurement and temperature control of lithium batteries to avoid overheating of lithium batteries, resulting in accidents.

In traditional technology, the NTC thermistor of the temperature detection sensor is manual plug-type, manually welded and then the contact terminal of thermistor is attached to the polymer core, and finally fixed with heat-conducting glue. Such a design is currently more commonly used, if the structure and size are satisfied, the SMD type NTC thermistor can make the lithium battery protective plate circuit has more advantages.

SMD type NTC thermistor has the advantages of high assembly density, small size, light weight, it’s size and weight of the SMD NTC thermistor is only about 1/10 of that of the plug-type thermistor, adopt SMD type NTC thermistor, can reduce the volume of electronic products by 40% to 60%, reduce weight by 60% to 80%. The great reliability, strong vibration resistance, low defected rate of welding spot, good high frequency characteristics of SMD type NTC thermistor, reduced interference of electromagnetism and RF, easy to achieve automation and improve production efficiency. Thus reduce costs to reach to 30% to 50%, save materials, energy, equipment, manpower, time and so on.

The invention relates to a lithium battery protected board circuit based on SMD type NTC thermistor, including charging circuits, discharge circuits, control chips, multiple resistance-capacitance elements, multiple MOSFET switching elements, and thermistors. The control chip detects the battery voltage and circuit current through multiple resistance-capacitance elements, and controls the on and off of the charging and discharge circuits through multiple MOSFET switching elements, with the thermistor series between multiple resistance-capacitance elements and batteries. The resistance-capacitance elements consists of thirty resistors and twenty-three capacitors, the number of MOSFET switching elements is four, and the lithium battery protected board circuit also includes four diodes, two voltage-regulator diodes, fuse and potentiometer.

Using SMD type NTC thermistor has the following advantages:

1.Save production and processing hours.The traditional manual welding is simplified and the production time was shortened.

2.Avoid displacement of contact terminal of plug-type NTC thermistors. If the contact terminal of the NTC thermistor is shifted to or around the heating device, there will be a large deviation in the power management IC for detection temperature.

3.Avoid short circuit.If NTC thermistor is damaged or exposed copper during material incoming or processing, it’s easy to connect with some components on the PCB board short circuit, so as to damage the PCB board or polymer core, and even cause safety accidents.

4.Avoid shifting and rupture, reduce the probability of human damage.The use of SMD type NTC thermistor can effectively avoid NTC thermistor is rupture during material incoming or processing, to prevent the cause of power management IC temperature detection errors.

SMD type NTC thermistor produced by EXSENSE Electronics Technology Co., Ltd., with good moisture resistance, reliability and stability. Its size of laminated ceramic structure is small and leadless, and is suitable for high-density surface mounting.