BMS and NTC Thermistors: Collaborative Optimization of Battery Management

I. What is BMS?

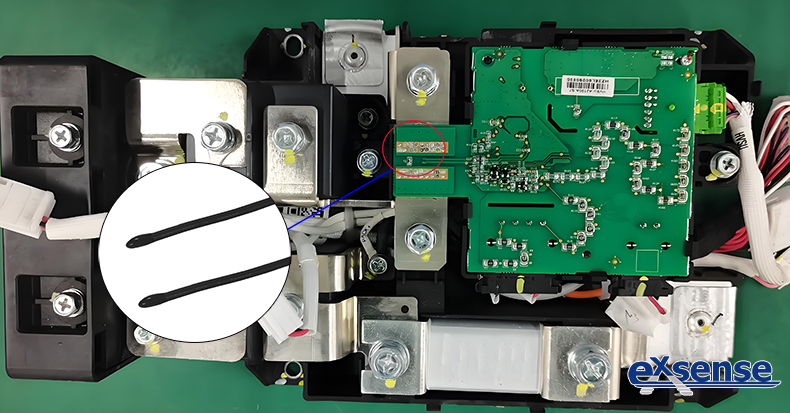

BMS (Battery Management System), the core control unit of a battery system, serves as the "brain" of a battery pack. Its primary functions include real-time monitoring of battery status, implementing protective controls, executing cell balancing, enabling communication interfaces, and managing thermal regulation. Typically installed inside the battery pack, the BMS is a critical component for ensuring safe battery operation. Through precise monitoring and regulation, the BMS effectively extends battery lifespan and enhances system performance.

Additionally, the BMS works synergistically with NTC (Negative Temperature Coefficient) thermistors. Leveraging the latter’s high sensitivity to temperature changes, the BMS achieves precise temperature control of the battery. This thermal management mechanism ensures batteries operate within safe and efficient parameters, guaranteeing stable performance for new energy vehicles and providing reliable power support.

II. How Do NTC Thermistors Function in BMS?

NTC thermistors are core sensors for thermal management in BMS. Their roles and implementation include:

1.Temperature Monitoring

NTC thermistors are installed inside or adjacent to the battery pack, continuously monitoring temperature fluctuations and feeding data back to the BMS. This ensures the battery operates within an optimal temperature range, as extremes (overheating or overcooling) degrade performance and longevity.

2.Overheat Protection

When an NTC sensor detects temperatures exceeding preset safety thresholds, the BMS triggers immediate actions—such as reducing charge/discharge currents or cutting off circuits—to prevent thermal damage or safety hazards.

3.Battery Performance Optimization

By providing accurate temperature data, the BMS dynamically adjusts charge/discharge strategies to optimize battery efficiency and output.

III. Key Design Considerations for NTC Integration in BMS

1.Placement Strategy

NTC sensors are typically positioned inside battery modules, on housing surfaces, or between cell groups. One NTC is deployed per 1–3 cells, covering both central and edge regions of modules to ensure comprehensive temperature detection.

2.Anti-Interference Design

Use shielded cables to minimize noise coupling from high-voltage lines. Incorporate RC filter circuits on BMS boards to eliminate signal jitter.

3.Calibration and Compensation

Periodically calibrate the NTC’s RT (Resistance-Temperature) table to correct long-term drift. Implement low-power measurement circuits to compensate for self-heating effects.

IV. Practical Application Examples

- EV BMS:

NTCs mounted on battery module tops monitor temperature spikes during fast charging. Data is relayed via CAN bus to the vehicle controller, enabling dynamic charging power limits. - Energy Storage System BMS:

NTCs installed at coolant inlet/outlets of liquid cooling plates optimize coolant flow rates in tandem with flow sensors, maximizing energy efficiency. - NTC Specifications for BMS:

Epoxy-encapsulated NTC thermistors are preferred, with customizable head sizes for compact installation and rapid thermal response. EXSENSE offers standard resistance values (10K, 50K, 100K) and B-values (3435, 3470, 3950, 3977), with tolerances of ±0.5%, ±1%, or ±2%. Custom parameters are available upon inquiry.

Conclusion

NTC thermistors enable precise temperature feedback, empowering BMS to dynamically regulate battery operations, prevent thermal runaway, and extend service life. As technology advances, NTCs will continue to play a pivotal role in enhancing the performance and reliability of battery management systems.

.jpg)