Application & Analysis of Fast NTC Temperature Sensor in Energy Storage

The energy storage mainly includes: battery management system (BMS), batter cabinets, CCS (Cells Contact System) energy storage, photovoltaic power generation, etc. With the continuous development of global technology, the energy storage industry is blooming and become indispensable with a long-term development.

Data of Global energy storage market:

In 2023, the global installed capacity of new type energy storage systems is 47.1GW/103.5GWh, and the global installed capacity of energy storage systems is about 16.1GWh. The global energy storage battery shipments will be 219.29GWh, the energy storage inverter shipments will be 73.37GW, and the BMS shipments will be 61.32GW.

NTC Temperature Sensor is significant in energy saving industry, here are some applications:

1.Battery Management System (BMS): By detectthe temperature of battery cells and modules, NTC Temperature Sensor can avoid overcharging, overdischarging oroverheating, and ensure the safe operation of the battery.

2.Energy storage cabinet: NTC Temperature Sensor detect the real time battery temperature of the energy storage cabinet. Once the temperature is too high, the corresponding heat dissipation or shutdown mechanism can be activated to avoid overheating or damage to the battery.

3.CCS energy storage: As core components, the NTC Temperature Sensor collect temperature data of the energy storage unit in real time, send the signals tothe system, detect potential safety hazards in time, and take corresponding actions to prevent or deal with them.

4.Photovoltaic power generation: usually, NTC Temperature Sensor monitor temperature changes in battery components andtransmit the signals. The system will adjust automatically in real time to improve photovoltaic power generation efficiency and the service life of battery components will be extended. Meanwhile, alarms for abnormal risks will be triggered to prevent accidents.

As an important part, NTC Temperature Sensor is helpful to enhance the safety and reliability of energy saving system with advance technology and improved efficiency. Additionally, the energy utilization efficiency and equipment service life will be upgraded.

Product picture:

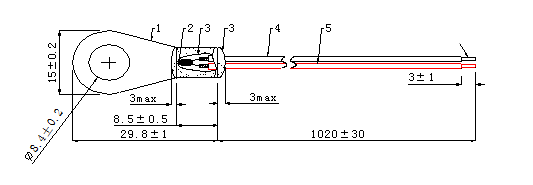

|

No. |

Material |

Specifications |

| 1 |

Housing |

R8-5M Ring Lug, brass with nickel plated |

| 2 |

Thermistor |

R25=10KΩ±1%, B(25/50)=3950K±1% |

| 3 |

Cable |

UL2651# 26AWG Black |

| 4 |

Connector |

Red |

Electronic characteristics:

1.Thermal time constant: ≤16 seconds, in water bath

2.Dissipation factor: about 2.8 W/℃in still air

3.Hi-pot test: AC 1500V 2mA 1 second

4.Insulation test: DC 500V in steel balls ≥100MΩ

5.Rated power: ≤10 mW

6.Operation temperature range: 0℃~ 80℃

Contact:

Ms. Tina Tang

Exsense Sensor Technology Co., Ltd

Tel:86-15813344362

email:sak@exsense.net

Web:www.exsense.net;www.exsense.com

Add:Xida Science Park, Duanzhou Dist., Zhaoqing , Guangdong