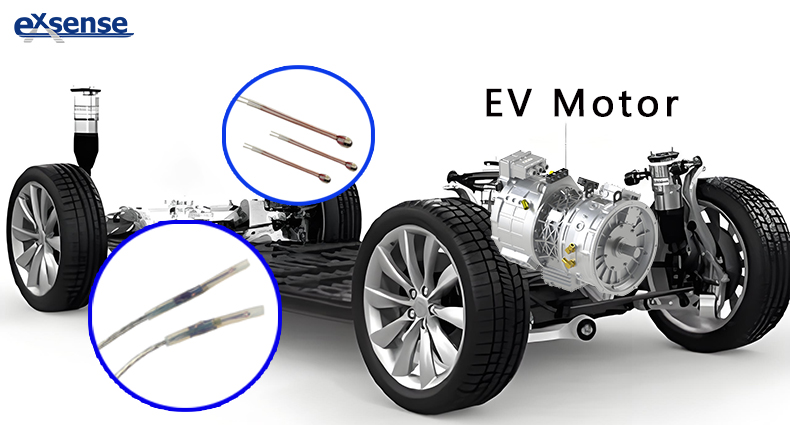

Drive motor stator relies on NTC temperature sensor

The drive motor of EV primarily converts electrical energy into mechanical energy to propel the car. This process is based on electromagnetic induction and Ampère’s force law: a rotating magnetic field is generated when current flows through the stator windings. This interacts with the rotor’s permanent magnets or induction windings, creating an electromagnetic force that drives the rotor to rotate, ultimately outputting mechanical energy to power the vehicle. As new energy vehicles operate at high speeds, temperature control of the motor stator becomes critical. NTC temperature sensors effectively prevent issues such as power reduction, shortened lifespan, and increased failure rates caused by motor overheating.

Negative Impacts of Excessive Stator Temperature:

- Reduced Motor Power: Rising temperatures increase internal resistance, impede current flow, and diminish motor output. Once the stator temperature exceeds the rated limit, power drops significantly.

- Shortened Motor Lifespan: High temperatures induce thermal expansion and stress, accelerating insulation aging and directly threatening motor durability.

- Increased Failure Rates: Overheating can cause winding short circuits, poor contact, and accelerated mechanical wear, compromising operational reliability and stability.

The stator within a drive motor comprises a core, enameled wires, protective covers, and coils. NTC temperature sensors are embedded within the coils to monitor stator temperature in real-time, ensuring safe operating conditions.

Applications of NTC Temperature Sensors in Drive Motor Stators:

- Temperature Monitoring & Protection

- NTC sensors are installed near or inside the stator to track winding temperatures. They rapidly detect fluctuations and relay data to the control system, preventing insulation damage and motor failure.

- Overheat Protection

- When temperatures surpass safety thresholds, the control system triggers measures like power reduction or shutdown to prevent damage and ensure long-term reliability.

- Performance Optimization

- Real-time temperature data enables dynamic adjustment of motor parameters for efficient operation across varying loads.

Typically, drive motors operate between -40°C to 125°C. However, prolonged high-speed operation can cause stator temperatures to spike beyond 125°C. To meet these demands, EXSENSE employs Teflon-sleeve-encapsulated, single-ended glass-sealed thermistors capable of withstanding up to 180°C, offering exceptional abrasion resistance, mechanical durability, and high-temperature stability. Standard resistance parameters include 10K, 50K, and 100K, with optional B values such as 3435, 3470, 3950, and 3977. Custom specifications are available upon request.

In summary, NTC temperature sensors ensure drive motors’ safety, efficiency, and reliability. They enable overheat protection, performance optimization, and improved energy efficiency through precise monitoring and intelligent control. As EV technology advances, the role of NTC sensors will grow increasingly vital.