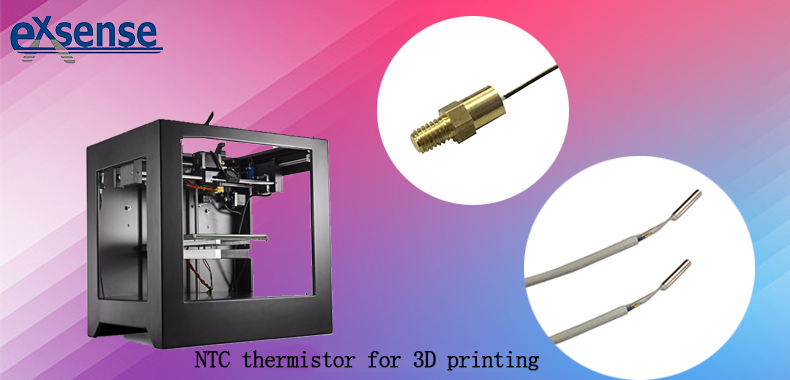

Fast Respond NTC thermistors for Printer

Temperature control is crucial in the 3D printing process. In order to ensure the stability of the printing process and the quality of the printed objects, an accurate temperature control system is essential.

Therefore,NTC thermistors plays an important role.

How does NTC thermistors work in 3D printing:

1.Precise control of printing temperature: NTC temperature sensors can monitor the temperature of 3D printer heating elements in real time and feed back temperature data to the control system. This enables the printer to accurately control the temperature of the printing process, alsoensuring the quality of the printed product.

2.Prevention of overheating: By detecting the temperature of the heating element, the NTC thermistors can detect overheating earlier and automatically adjust the power of the heating element to prevent the heating element from overheating. This not only prolongs the service life of the heating element, but also protects the printer from damage.

3.Safety: When the heating element is overheated to a dangerous level, the NTC thermistors can release an alarm in time to remind the user to take measures to prevent accidents.

When choosing NTC thermistors for 3D printers, you need to consider the following factors: the printer type, printing material characteristics, and printing environment. Generally speaking, NTC thermistors with high accuracy, fast response speed, and good stability are ideal choices. In addition, you also need to consider the special needs of 3D printing, such as the size and installation method of the thermistors.

In general, NTC thermistors play a vital role in the 3D printing process. They can accurately control the printing temperature, prevent overheating, and provide safety protection. Choosing the right NTC thermistors and using it correctly is the key to ensuring a stable, safe, and efficient 3D printing process.