NTC Thermistor Resistance-Temperature Conversion Algorithms and Technical Analysis

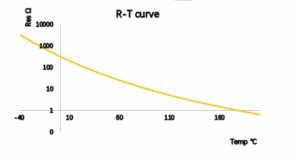

NTC thermistors are temperature-control components based on semiconductor materials, exhibiting a nonlinear decrease in resistance as temperature rises. As a quintessential application of the Negative Temperature Coefficient (NTC) effect, these devices leverage the physical mechanism of internal carrier concentration changes with temperature for sensing. They are widely used in precision temperature measurement, compensation, and electronic thermal control modules.

NTC thermistors are temperature-control components based on semiconductor materials, exhibiting a nonlinear decrease in resistance as temperature rises. As a quintessential application of the Negative Temperature Coefficient (NTC) effect, these devices leverage the physical mechanism of internal carrier concentration changes with temperature for sensing. They are widely used in precision temperature measurement, compensation, and electronic thermal control modules.

Ⅰ.Working Mechanism and Material Properties

NTC thermistors are typically fabricated by high-temperature sintering of transition metal oxides (e.g., Mn, Ni, Co spinel-structured ceramics) into polycrystalline ceramic bodies. Their resistance-temperature characteristics stem from changes in material band structure: as temperature increases, thermal excitation intensifies, promoting more electrons to jump into the conduction band and participate in electrical conduction, resulting in significantly reduced resistivity. Typical NTC devices exhibit resistance changes spanning several orders of magnitude within the -50°C to 300°C range.

NTC thermistors are categorized by application:

NTC thermistors are categorized by application:

- Power-type NTC thermistors

- Compensation-type NTC thermistors

- Temperature-sensing NTC thermistors

Structural classifications include:

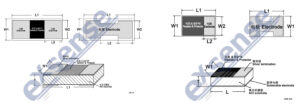

[Product dimension diagrams for thermistor chips, glass-encapsulated thermistors, and chip thermistors would be inserted here.]

Ⅱ.Temperature Performance and Resistance-Temperature Conversion Models

Two key parameters define the temperature response of NTC thermistors:

- Nominal Zero-Power Resistance (R₂₅):

The DC resistance was measured at a reference temperature of 25°C (298.15K) under zero self-heating conditions. Standard tolerance grades include ±1%, ±2%, and ±3%.

- Material Constant (β-value):

A dimensionless parameter representing temperature sensitivity (thermal sensitivity index). For industrial-grade products, β typically ranges from 3000K to 5000K. It is calibrated using a two-temperature method:

- β = [ln(R₁/R₂)] / [(1/T₁) – (1/T₂)]

Where R₁/R₂ are resistances (Ω) at temperatures T₁/T₂ (K).

- Resistance-Temperature Conversion Algorithm

While the three-parameter Steinhart-Hart equation precisely describes NTC nonlinearity, the simplified two-parameter B-equation is commonly adopted in engineering practice:

- Rₜ = R₂₅ · e<sup>β(1/T – 1/298.15)</sup>

The inverse conversion (resistance → temperature) is:

- T = [1 / ( (1/298.15) + (1/β) · ln(Rₜ/R₂₅) ) ] – 273.15

Where:

- Rₜ = Measured resistance at target temperature (Ω)

- T = Absolute temperature (K), converted to Celsius (°C)

Ⅲ.Technical Characteristics and Applications

- Key Application Scenarios

- NTC thermistors enable five core functions via resistance-temperature conversion:

- Inrush Current Limiting: Exploits high resistance at low temperatures to suppress power-on surge currents.

- Precision Temperature Sensing: Achieves ±0.1°C accuracy with ADC circuits.

- Temperature Compensation Networks: Corrects thermal drift in crystal oscillators.

- Liquid Level/Flow Detection: Indirectly measures medium status via thermal conduction.

- Overheat Protection: Forms thermal cutoff switches or fuse protection circuits.

- Engineering Advantages

- NTC thermistors dominate applications due to their technical strengths:

- Cost Efficiency: Lower unit cost vs. platinum RTDs.

- Form Factor Diversity: >20 package types (axial, SMD, glass-encapsulated, etc.).

- Design Flexibility: Output linearization via parallel/series resistor networks.

- Response Speed: Thermal time constant (τ) as low as 0.3 sec (package-dependent).

Development Outlook

With superior thermal sensitivity and engineering adaptability, NTC thermistors have penetrated strategic sectors like consumer electronics, automotive, industrial control, and aerospace. Driven by IoT demand for miniaturized, intelligent temperature sensing, integrated NTC solutions (e.g., digital-output NTC sensors) are emerging as R&D hotspots, with the market projected to grow at >8% CAGR.