NTC Thermistors in Home Charging Piles: From Temperature Sensing to Safety Optimization

Ⅰ.Industry Context

Driven by global carbon neutrality initiatives, the electric vehicle (EV) industry is experiencing explosive growth, propelling exponential expansion in home charging pile installations and usage frequency. According to the latest data from the China Charging Alliance, as of the end of 2024, China‘s charging infrastructure has surpassed 12.8 million units, marking a 49.1% year-on-year increase, with the vehicle-to-pile ratio optimized to 2.4:1. This underscores the rapid market expansion and immense potential of home charging infrastructure.

Ⅱ.Thermal Management Challenges

For charging pile manufacturers, scaling production capacity must align with heightened vigilance toward thermal management. Charging piles generate substantial heat during energy conversion and transmission, causing abrupt temperature rises. Excessive temperatures degrade operational efficiency, accelerate component aging, and shorten service life but also pose severe safety risks such as short circuits and fires, endangering users and property. Consequently, establishing an efficient and reliable thermal management system is critical to ensuring stable operation.

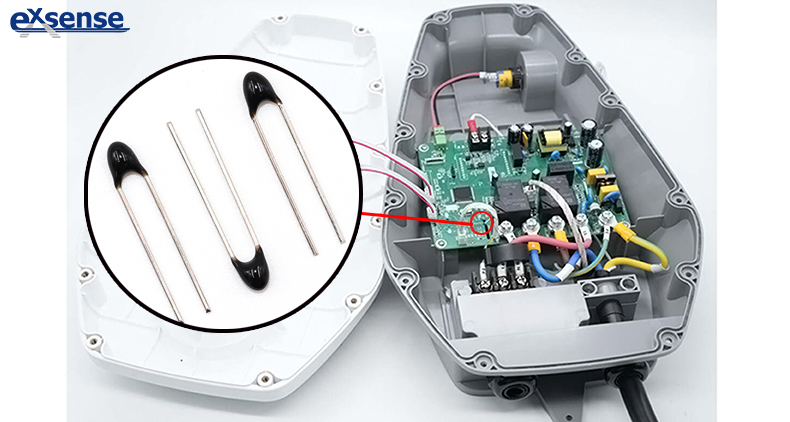

NTC (Negative Temperature Coefficient) thermistors are high-precision and robust temperature sensors that provide real-time monitoring of internal temperature fluctuations. Upon detecting abnormal temperature spikes, these sensors activate cooling mechanisms to prevent equipment damage and safety hazards, ensuring operational reliability.

III. Charging Pile Operational Principles

The core function of charging piles is converting grid alternating current (AC) to direct current (DC) suitable for EV battery storage. Integrated charging controllers dynamically adjust output current and voltage based on battery state-of-charge (SoC), charging demands, and real-time parameters (voltage, current, temperature), ensuring both charging efficiency and safety. EVs connect to charging piles via charging interfaces, forming a closed-loop circuit for energy transfer.

- Thermal Management Imperatives

During operation, energy conversion processes inherently generate heat, elevating device temperatures. Prolonged overheating compromises charging efficiency, induces component failure and escalates safety risks. Thus, thermal management systems must rigorously monitor and regulate internal temperatures to maintain optimal operating conditions (-20°C to 50°C).

Charging piles are categorized into AC ("slow charging") and DC ("fast charging") variants. AC charging relies on onboard chargers (OBCs) within EVs to convert AC to DC, while DC charging piles integrate rectifiers to convert grid AC to DC directly. Both types face thermal stress from overcharging/discharging cycles, necessitating precise temperature control across critical components.

Ⅳ.NTC Thermistor Implementation Strategies

- Temperature Monitoring & Regulation

- NTC thermistors are strategically deployed in high-heat zones (power modules, controllers, charging gun connectors) to track temperature gradients. When temperatures exceed predefined thresholds (e.g., >50°C), systems initiate countermeasures such as activating cooling fans or throttling charging power.

- Overheat Protection

- At critical temperatures (>50°C), NTC sensors trigger alarms and disconnect circuits, mitigating risks of thermal runaway and equipment damage.

- Charging Efficiency Optimization

- NTC sensors enhance charging efficiency across varying environmental conditions while prolonging device lifespan by enabling dynamic power adjustments based on thermal feedback.

Ⅴ.Application Case Studies

- Power Module Monitoring

- Location: Integrated within IGBT modules

- Sensor Type: Glass-encapsulated SMD thermistors

- Function: Ensures power modules operate within 85°C limits under high-current (200-600A) conditions.

- Charging Gun Connector Monitoring

- Design: 304 stainless-steel tubular encapsulation

- Performance: Response time τ <1s, withstanding 10,000+ mating cycles.

- Controller Board Monitoring

- Integration: Epoxy-coated NTCs soldered onto PCBs

- Data System: RS485 bus transmits thermal gradients to ANSYS-based simulation platforms, achieving an 83% reduction in thermal runaway risks through predictive diagnostics.

VII. Conclusion

EXSENSE’s NTC thermistors are pivotal in advancing charging pile thermal management and enhancing operational safety, efficiency, and longevity. As EV adoption accelerates, demands for sophisticated thermal systems will intensify. Leveraging their precision, reliability, and rapid response, NTC thermistors will remain indispensable in supporting scalable and sustainable EV infrastructure development.